Envirep is the Authorized Distributor for Vogelsang

Envirep is the Authorized Distributor for Vogelsang. Envirep offers Vogelsang products to the municipal water and wastewater markets in Delaware, Maryland, Washington, D.C., Pennsylvania, and New Jersey. Vogelsang is a world leader in designing and manufacturing rotary lobe pumps, XRipper twin-shaft grinders, and the RotaCut macerator.

About Vogelsang

Vogelsang is located in Ravenna, Ohio, and is a leading manufacturer of rotary lobe pumps, XRipper twin-shaft grinders, and the RotaCut macerator.

Vogelsang is a reliable and innovative manufacturer of wastewater technology, offering customers equipment to efficiently operated sewage collection systems and sewage treatment plants.

PRODUCTS OFFERED BY VOGELSANG

XRipper Twin Shaft Grinders

The XRipper Twin Shaft grinders provide high-volume coarse grinding for systems where large amounts of debris may be present in the wastewater or sludge. They protect downstream pumps and process components, preventing clogs, blockages, and damage. The monolithic ripper rotors are made of hardened high-quality steel block.

Typical Applications

- Wastewater pumping stations

- Septage and FOG receiving stations

- Influent screenings grinding

- Primary scum

- WWTP sludge

- Dewatering equipment feed

- Hospitals and nursing homes

- Jails and prisons

- Resorts

- Truck stops and rest areas

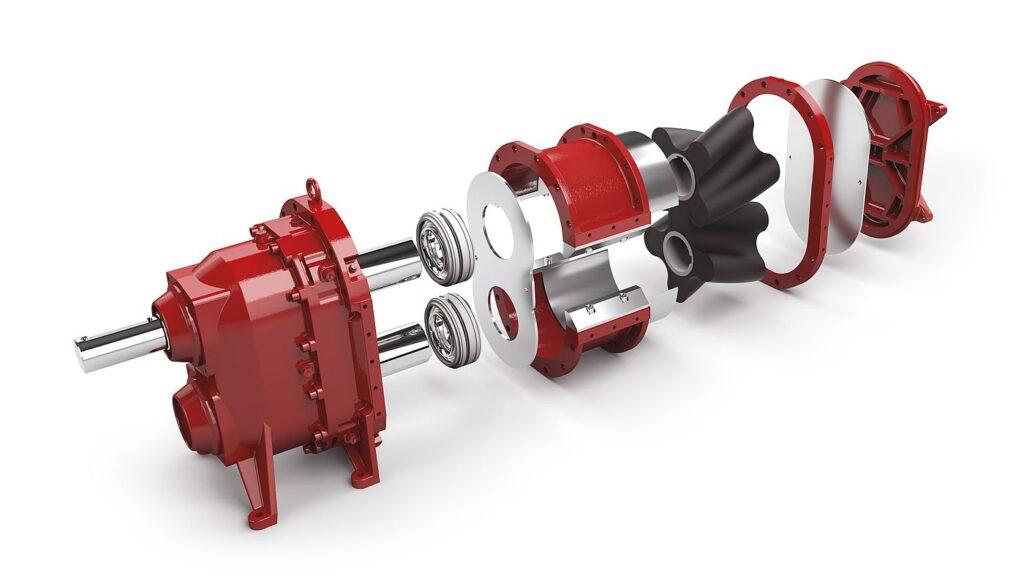

Rotary Lobe Pumps

Vogelsang’s rotary lobe pumps are ideal for tough sludge applications involving heavy solids, viscous sludge, and abrasive liquids. Vogelsang pumps are easy to maintain. The entire wet end is accessed by removing the front cover. Wear parts are replaced without disturbing connected piping.

Rotary lobe pumps are positive-displacement type pumps that use two or more lobes rotating around parallel shafts in the pump’s body to move liquids. They provide a compact, easy-to-maintain solution that can handle various applications. The movement of the pump’s lobes cause the pump to discharge a specific amount of fluid each revolution. Therefore, the pump’s output is easily controlled by varying the pump’s speed with a variable frequency drive (VFD).

Typical Applications inside Treatment Plants

- Septage and FOG receiving

- Primary sludge

- Primary scum

- Return-activated sludge (RAS), waste-activated sludge (WAS)

- Thickened waste-activated sludge (TWAS)

- Digester feed and recirculation

- DAF Thickening

- Dewatering equipment feed

- Slurries

RotaCut Inline Macerators

RotaCut Inline macerators chew up solids, such as rags and other objects, before they cause damage to downstream pumps and equipment. Heavy solids such as stones and metal objects settle to the bottom of the pot, and removed from the stream entirely.

Macerators, or single-shaft grinders, are installed in pipelines. They require liquid flow through the cutter assembly to operate. Macerators reduce the sludge solids into small, manageable particles, keeping pumps and downstream equipment safe. Solids such as hair, wipes, and rags are finely cut, allowing them to easily pass through downstream equipment without clogging. Macerators are best suited for advanced cutting after the headworks of a wastewater treatment plant.

Typical Applications inside WWTPs

- Fats, oils, and grease (FOG) Receiving

- Septage receiving

- Primary sludge

- Primary scum

- Return-activated sludge (RAS), waste-activated sludge (WAS)

- Thickened waste-activated sludge (TWAS)

- Digester feed and recirculation

- Dewatering equipment feed

- Plastic reduction for land application of biosolids

Genuine Vogelsang Replacement Parts

At Envirep, we will help you choose the best Vogelsang parts for your equipment. Our goal is to provide easy-to-operate, low-maintenance components to ensure your equipment is back in service quickly.

Precise tolerances are critical to the performance of Vogelsang equipment. Even slight variances can generate significant inefficiencies, and using non-OEM components dramatically increases the risk of equipment failure. Use genuine Vogelsang parts to avoid these problems.

Envirep is the Authorized Distributor for Vogelsang. Please contact Envirep if you would like additional information or an on-site demonstration.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Contact Envirep at 717-761-7884 or sales@envirep.com.

By Michael Gillespie, President at Envirep