Greasezilla Removes FOG

Fats, oils, and grease (FOG) are common problems in wastewater collection systems and treatment plants. When fats, oils, and grease are improperly disposed of down drains or sewers, they accumulate and create blockages in the sewer system, leading to backups and overflows.

Many wastewater treatment facilities accept trucked-in waste with high levels of FOG. Utilities strive to remove this material from typical wastewater to avoid clogging in the collection system, reduce maintenance and backups, and avoid the increased oxygen demand of these wastes in the treatment systems. They also reuse the energy that is contained within the FOG.

Trucked-in waste includes septage and other high-strength wastes such as grease trap waste, sewage wet well cleaning waste, and waste from food processors.

Problems with FOG at WWTPs

- Reduces the efficiency of treatment processes

- Accumulates in pipes, pumps, and other equipment, leading to blockages, clogs, and equipment failure

- Increases the oxygen demand in secondary treatment systems

- Creates a scum layer in aeration tanks which reduces the oxygen transfer efficiency

- Unpleasant odors

- Affects the quality of WWTP effluent

- Increases treatment and disposal costs

- Excessive foaming in aeration tanks and digesters

Despite the problems with FOG, it offers significant benefits from tipping fees and feedstock for anaerobic digesters that produce biogas, which can be beneficially used as fuel.

FOG can be difficult to remove

FOG can be challenging to remove from wastewater. However, many facilities install specialized FOG separating processes to generate valuable products such as biofuel, which can then be sold or used to create energy. By generating income from the sale of biofuel, wastewater treatment facilities can offset some of the costs associated with FOG management. By managing FOG effectively, wastewater treatment facilities can improve their operations, reduce the risk of environmental harm, and generate income.

Greasezilla removes FOG

Greasezilla is the leading provider of FOG Separation equipment. It is a turnkey standalone system that optimizes FOG separation while producing a high-quality brown grease advanced biofuel.

Greasezilla leaves nothing to be landfilled and has a total operating cost of 1 to 2 cents per gallon. The separation process produces a high-quality advanced biofuel, making Greasezilla the ideal front-end pretreatment system for FOG waste.

The Greasezilla unit runs on brown grease. About five percent of the brown grease from each batch is returned to the system and used as fuel.

The GreasezillaSM system is installed before the headworks of a wastewater treatment facility. A standard system includes dual 10,000-gallon, double-wall, insulated steel tanks. As one tank heats and separates, the other is harvested, drained, and reloaded. GreasezillaSM is a batch process that does not require chemicals or polymers.

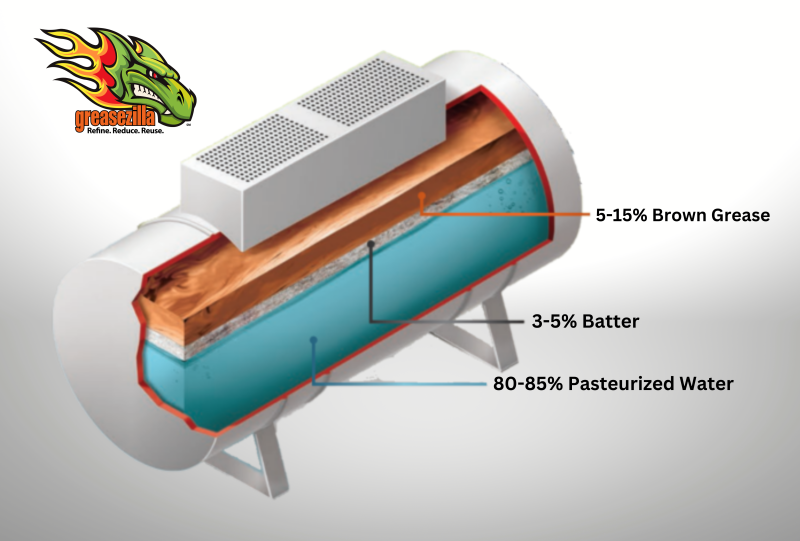

Greasezilla separates grease trap waste into three distinct layers:

Brown Grease (Biofuel)

Brown grease is a byproduct of the food industry that contains a mixture of fats, oils, and solids. It comes from the cleaning of equipment used to produce fried foods. Approximately 5 to 15 percent of the finished volume is brown grease or advanced biofuel (ABF). Five percent of the Biofuel is used to fuel the Greasezilla℠. The remaining 95 percent is used for other heat requirements at the plant or as a salable fuel substitute.

Yellow Grease (Batter)

Yellow grease (Batter) is from cooking oil processing and cleaning and it contains organic materials, such as fats, oils, and grease. Yellow grease makes up 3 to 5 percent of the finished volume and is an excellent feedstock for anaerobic digesters. Removing the brown grease and feeding the yellow grease to anaerobic digesters at a relatively uniform rate minimizes the potential for digester upsets and increases biogas production.

Residual Water

Eighty to Eighty-Five percent of the final volume is residual water is discharged back to the wastewater treatment facility.

End Results of Greasezilla

The Greasezilla FOG separation process eases the financial burden of ever-increasing operation and maintenance costs associated with FOG management and helps wastewater treatment facilities:

- Improve WWTP effluent

- Reduce O&M costs

- Reduce the risk of environmental harm

- Generates income

- Provides a sustainable energy source

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Contact Envirep at 717-761-7884 or sales@envirep.com.

By Michael Gillespie, President at Envirep