ANITA™ Mox for Nitrogen Removal

Anaerobic sludge digestion is a highly efficient method for treating biosolids at large municipal wastewater plants. After digestion, the sludge undergoes dewatering, and the resulting centrate or filtrate is reintroduced into the main plant for further treatment. However, a significant challenge arises with this centrate/filtrate stream. It contains remarkably elevated ammonia levels, typically from 800 mg/l to 1200 mg/l. In some cases, mainly when the plant employs a thermal hydrolysis process (THP) before anaerobic digestion, these ammonia concentrations can soar even higher. The presence of high concentrations of BOD and COD is also a common issue, particularly in plants using THP.

This recycle flow increases the ammonia and total nitrogen loading to the primary plant treatment process by up to 25% while adding only about 1% to 2% to the plant influent flow.

The recycle flow can be detrimental to plant design/operations in several ways:

- The recycled nitrogen load not only increases the aeration requirement to achieve nitrification but also adversely impacts the stability of the treatment process.

- It requires more process tank volumes.

- It can require adding an external carbon source, such as methanol, to achieve low total nitrogen limits.

- The increased oxygen requirements and additional chemical consumption contribute significantly to facility energy consumption and operational costs.

- When the biological activity slows in cold climates, the extra ammonia load can cause the treatment plant to exceed the NPDES permit limits, especially when stringent.

Veolia’s ANITA™ Mox Process

Veolia’s ANITA™ Mox process effectively treats the recycle flow from anaerobic digesters with high ammonia concentrations and solves the problems of returning high ammonia concentrations to the main plant treatment process. In addition, it helps save energy and O&M costs by reducing the demand for aeration and chemicals.

Veolia/Kruger is a leader in providing the media-based de-ammonification process to the US municipal market. The ANITA™ Mox process is available in two different configurations, MBBR (Moving Bed Biofilm Reactor) and IFAS (Integrated Fixed Film Activated Sludge), to attain a single-stage de-ammonification process using anammox bacteria. The process can achieve greater than 90% removal of ammonia and 75-85% total nitrogen removal. Furthermore, it accomplishes these removals with considerably less energy than conventional nitrification-denitrification without needing an external carbon source.

Anammox Bacteria

The anammox bacteria, discovered in wastewater sludge in the early 1990s, exists naturally in marine and freshwater habitats. The word anammox was derived from ANoxic AMMonia OXidizing bacteria. They are unique in their ability to oxidize ammonia and reduce nitrite to produce nitrogen (N2) gas.

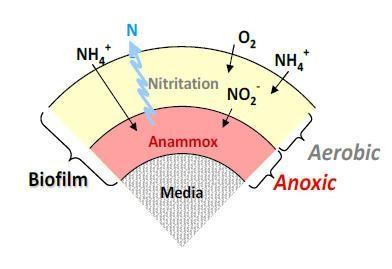

The ANITA™ Mox process utilizes anammox bacteria to convert ammonia to nitrogen gas. It is performed in two steps: aerobic nitritation and anoxic ammonia oxidation. Anammox bacteria provides many advantages over traditional nitrogen removal processes, especially in treating ammonia-rich waste streams.

ANITA™ Mox: MBBR Configuration

The two steps occur in a one-stage biofilm process in different biofilm layers on the carriers: nitrification (aerobic) in the outer layer and anammox (anoxic) in the inner layer. This is achieved within a single MBBR reactor tank. Temperature, pH, and oxygen levels are maintained within the reactor to allow the anammox bacteria to grow as a biofilm on AnoxKaldnes media carriers. Due to the biofilm being securely attached to the protected areas of the media carriers, long sludge ages are easily maintained to offset the slow growth rate of the anammox bacteria, making the ANITA™ Mox system a simple, stable and robust de-ammonification technology. All the system benefits of the proven MBBR technology apply to MBBR ANITA™ Mox, including easy retention of media carriers and critical biomass, maintenance-free SS air grids and media retention screens, and a simple flow-through process.

Benefits of MBBR ANITA™ Mox

- Biofilm is resistant to flow and load variations and not prone to anammox washout.

- Simple and stable flow-through process.

- Easy to operate and maintain.

- The operator-friendly process does not require a champion operator.

- Media, aeration grids, and media retention screens are maintenance-free.

- Easy to expand capacity by addition of media.

- Tolerates high influent TSS influent without requiring pretreatment and therefore provides CAPEX savings.

- Do not require micronutrients, antifoaming, or other special agents.

- It can be in idle mode without feed for extended periods.

- Recovers quickly from process upsets such as power shutdowns, overfeed, under aeration…etc.

- The process tolerates temporary limitations or fluctuations in pH, temperature, and parameter concentrations.

- HDPE carriers last the life of the system.

- The Anita Mox process is proven to withstand short-term and prolonged system shutdowns. The system can be placed into low-flow or low-loading mode. This allows the facility to have flexibility in dewatering schedules and perform routine or emergency maintenance to their digesters or dewatering equipment without significantly impacting system performance.

- Anita Mox is the best technology for treating centrate/filtrate.

ANITA™ Mox: IFAS Configuration

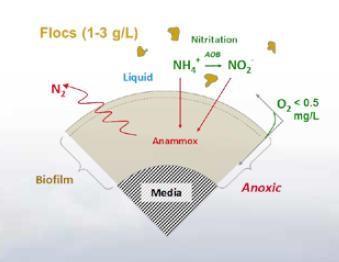

The IFAS (Integrated Fixed Film Activated Sludge) configuration of the ANITA Mox process combines biofilms attached to media carriers and mixed liquor suspended solids (MLSS) and offers distinct benefits.

In the ANITA™ Mox IFAS system with anammox biofilms attached to media carriers, the MLSS concentration is maintained using a small sludge settling zone. The nitritation step, or the conversion from ammonia to nitrite, occurs in the MLSS. The de-ammonification step occurs mostly in the biofilm attached to the media carriers. Nitrite production is the limiting step in anammox conversion rates. Moving the nitritation step to the suspended phase increases nitrite production, thus providing an overall increase in anammox conversion and removal rates.

Added benefits of IFAS ANITA™ Mox include the following:

- Nitrogen removal rates are over two times higher

- Reduced footprint

- Lower dissolved oxygen levels are required, further improving energy savings.

- Handles the presence of high influent and potentially recalcitrant COD and other toxic substances better

- Best suited for centrate/filtrate treatment from anaerobic digesters following THP and treating food waste

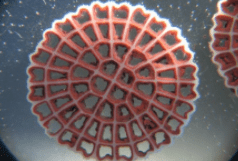

ANITA™ Mox Carriers

The ANITA™ Mox process hinges on a crucial component: the AnoxKaldnes carriers. These carriers offer a generously large and sheltered surface area for the biofilm to attach, creating optimal conditions for biological activity when suspended in water. Their design plays a pivotal role in enhancing oxygen and substrate transfer efficiencies by maintaining an ideal media bed depth. If the bed is too shallow, it compromises biofilm protection and attachment ease. Conversely, if it’s too deep, liquid mixing and biofilm scouring become challenging, leading to reduced oxygen and substrate transfer efficiencies and overall performance.

What sets these carriers apart is their unique design, enabling the retention of anammox bacteria within the reactors. This design significantly mitigates the risk of anammox washout, a problem commonly encountered in other suspended growth technologies. By minimizing this risk, the AnoxKaldnes carriers contribute significantly to the efficiency and stability of the ANITA™ Mox process.

Conclusion

Municipal wastewater treatment plants (WWTPs) are facing increasingly stringent effluent limits, necessitating the adoption of cost-effective technologies to reduce ammonia and total nitrogen (TN) levels. Among the available options, the ANITA Mox process stands out due to its unique advantages and cost-saving capabilities. It has quickly become one of the most widely adopted de-ammonification technologies for treating centrate/filtrate from anaerobic digesters. This process efficiently reduces ammonia and TN loading in the recycled water sent back to the main treatment process.

Leading the charge in providing this media-based de-ammonification solution to the US municipal market is Veolia/Kruger. The Veolia US team collaborates directly with Veolia Engineering and Research Institute in France and AnoxKaldnes AB in Sweden, ensuring the integration of the latest knowledge and developments into the design of this technology.

Over the past decade, the ANITA™ Mox process has been installed at more than 35 full-scale facilities. It is effective at treating centrate, filtrate, and pressate from both conventional anaerobic digesters and those following thermal hydrolysis processes (THP). This widespread implementation showcases the technology’s reliability and effectiveness in meeting the demanding requirements of modern wastewater treatment.

Veolia’s ANITA™ Mox process is the market’s most reliable sidestream de-ammonification process that offers distinct benefits with different configurations.

For more information, brochures, or presentations, please get in touch with Envirep/TLC at sales@envirep.com or call 717-761-7884.

By Michael J. Gillespie, P.E., President of Envirep

Envirep/TLC is a manufacturer’s representative serving the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, and Virginia.

We represent manufacturers of equipment used to pump, treat, and dispose of wastewater and biosolids. We also represent manufacturers of equipment used to pump, treat, distribute, and store potable water.