Environetics Clearwell Baffles

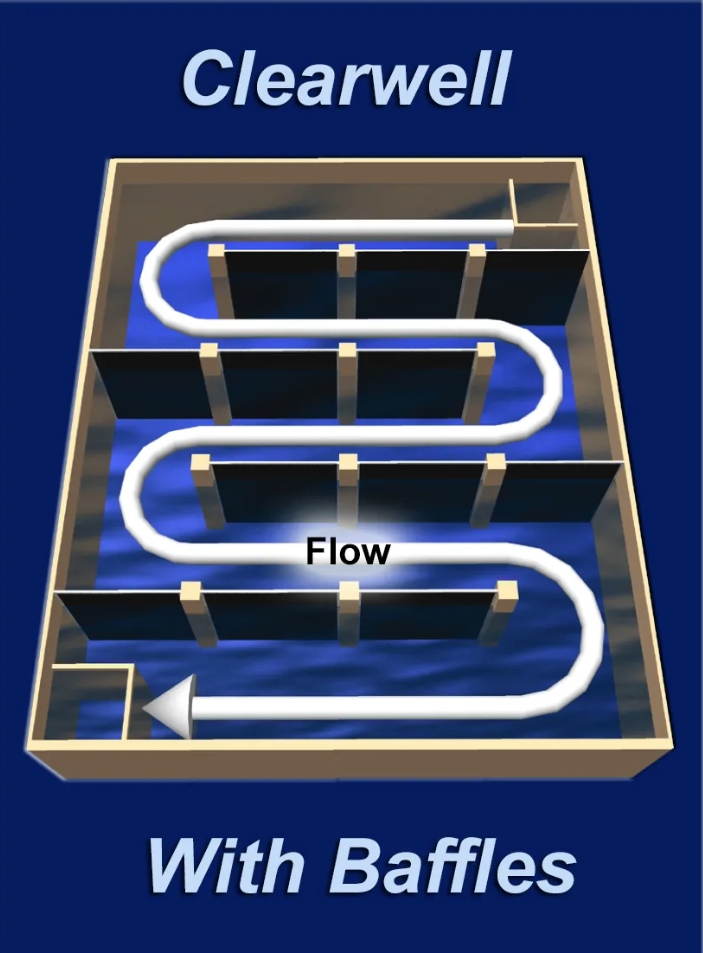

Environetics Clearwell baffles are installed in Clearwells to upgrade the disinfection system performance to meet Safe Drinking Water Act (SDWA) requirements regarding Contact Time (CT).

Benefits of Environetics Clearwell Baffles:

- Prevents short-circuiting

- Improves disinfection efficiency

- Provides longer detention time

- Improves mixing

- Eliminates dead zones

- Improves water quality

- Compliance with regulations

- Cost savings

Baffles increase the baffling factor (BF) in a Clearwell. For example, a low BF (0.1) indicates poor hydraulics caused by a low length-to-width ratio and high inlet and outlet flow velocities in the tank, resulting in short-circuiting. Conversely, a high BF (1.0) shows perfect plug flow through a tank with no dead space, high length-to-width ratios, and no short-circuiting.

Clearwell Baffles increases the detention time in the basin by diverting the flow of water on a longer path. This helps ensure the disinfectant has adequate contact time to kill harmful bacteria or viruses in the water. In addition, this extended detention time helps produce predictable disinfection results to meet the treatment standards set out in the SDWA.

Clearwell Baffles Increase Retention Time

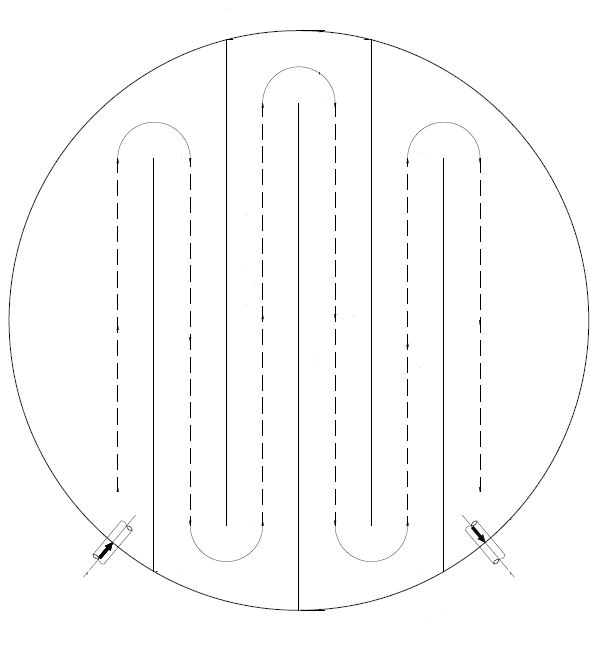

The Environetics DIRECTOR™ III Clearwell Baffles are designed to meet SDWA treatment standards cost-effectively.

Attach the flexible panels of reinforced synthetic rubber directly to new or existing Clearwell walls, floors, roofs, or columns. These panels become an innovative barrier, actively diverting the water flow along a longer path. This extended journey increases detention time within the basin, leading to more efficient and predictable disinfection results.

Adding Clearwell Baffles is a cost-effective way to upgrade existing disinfection systems to meet required treatment standards without costly modifications or the construction of new treatment facilities.

Environetics Clearwell Baffle Materials

Environetics uses a high-quality potable grade synthetic geomembrane material. In addition to providing long-term performance, this material is also safe to use in drinking water systems.

As a polyester-reinforced membrane, it provides excellent dimensional stability and structural integrity, making it durable and long-lasting. Additionally, this material is certified by NSF International Standard 61 for use in public drinking water supply systems.

NSF Standard 61 certification ensures that the material has been tested and evaluated to meet strict health and safety requirements, including the ability to withstand exposure to chemicals commonly found in a drinking water treatment system.

makes installation easy.

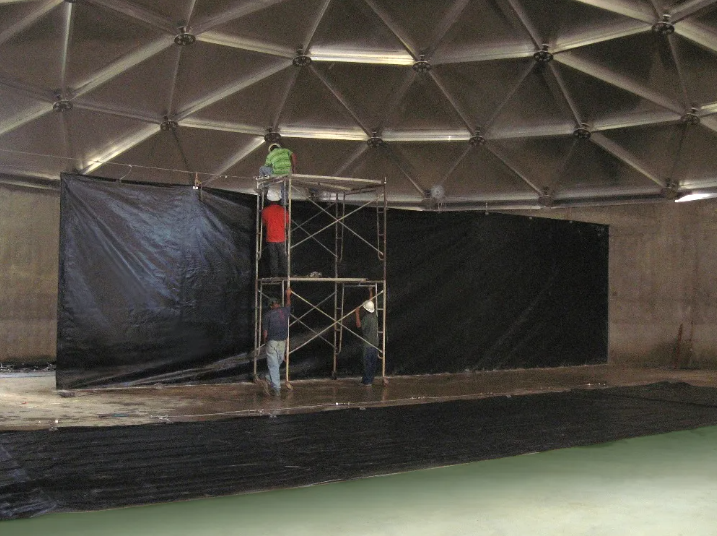

Installation Flexibility

The flexible panel design of the Environetics Clearwell Baffle systems makes installation easy, even in new or existing below-grade or above-ground structures. The panels can be rolled or folded for easy transportation through manways or inspection hatches. This feature eliminates costly structural modifications and makes the installation process more efficient and cost-effective.

Installation flexibility makes the Environetics Clearwell baffle system an ideal solution for water treatment facilities looking to upgrade their disinfection system and cost-effectively meet SDWA standards while minimizing disruption to their operations.

Engineering Drawings and Assistance

Environetics designs each Clearwell Baffle custom to the specific tank dimensions. Engineered drawings are provided to allow for a simple installation process. Site supervision of the installation is available upon request.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep today.

By Michael Gillespie, President at Envirep/TLC