Gorman-Rupp Centrifugal Pump Training

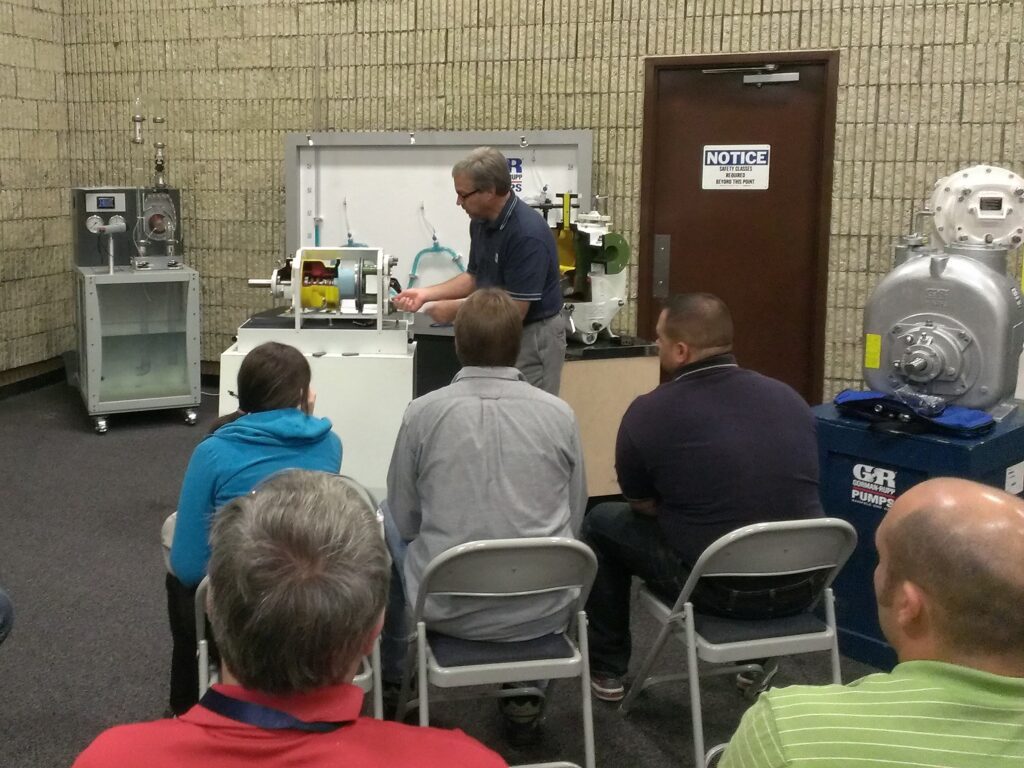

Several municipal wastewater managers from Maryland recently attended the Gorman-Rupp centrifugal pump training in Mansfield, Ohio, to learn about Gorman-Rupp suction lift pumps and submersible pump technology.

Gorman-Rupp has trained thousands of water industry professionals in the latest advancements in wastewater pumping technologies. Taught by a team of instructors, the Gorman-Rupp factory pump schools educate attendees on pumps, hydraulics, applications, troubleshooting and station components. The factory training allows you to experience the pump manufacturing process from start to finish.

The Training Includes:

1) Highly automated machine shop with robotics machining of pump parts, pattern shop, pump assembly, pump testing, pumping station assembly, electrical panel shop, mechanical and electrical engineering.

2) Extensive spare parts inventory. Gorman-Rupp has an extensive inventory of pumps and parts. And, Envirep has a large inventory of Gorman-Rupp spare parts in Camp Hill, PA.

3) Demonstrations of pump maintenance techniques, including assembly and disassembly, mechanical seals, impeller clearance adjustment, v-belt drive adjustment, etc.

4) Discussion of pump troubleshooting techniques, including the use of gauges, shutoff head tests, pump performance curves, and system head curves.

5) Packaged pumping station features, including construction materials, valves, fittings, ancillary components, control panels, electrical components, motors, level control systems, and alarms.

6) Interactive instruction on system design and typical wastewater pump applications.

7) Glass-faced pump demonstrations of system head curve and pump performance curve interaction, net positive suction head, and pump-priming vs. repriming.

8) Demonstrations of damaging hydraulic conditions such as NPSH cavitation, impeller tip cavitation, suction cavitation, vortexing, and air entrainment.

9) Demonstration showing the importance of properly functioning air release valves at force main high points.

Pump Room Demonstration

The most essential part of the training is when customers visit the “pump room” to see pump hydraulic demonstrations. This high-tech demonstration simulates multiple pump operations and provides invaluable insight into how pumping systems are applied.

Committed to Quality

Gorman-Rupp’s commitment to quality goes beyond manufacturing the best products possible. Customers are the ultimate judge of quality, and they seek durable, reliable, and long-lasting products. From the initial planning stage of a project through design, startup, and service, Gorman Rupp is committed to excellent customer service.

Click here to view a complete list of our products.

Click here to learn about Gorman-Rupp pump products.

Please get in touch with us to attend a Gorman-Rupp factory tour.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Dwight Swan, Sales Engineer at Envirep/TLC