Aqua-Aerobic OxyStar Aspirator Aerators

OxyStar Aspirator Aerators by Aqua-Aerobic Systems are used in municipal and industrial wastewater applications to provide aeration and mixing for:

- Aerated lagoons

- Equalization basins

- Aeration tanks

- Aerobic digesters

- Sludge holding tanks

- Oxidation ditches

- Post aeration

The OxyStar Aspirator Aerators provide superior fine bubble aeration and mixing, allowing for easier installation and less maintenance than other aeration systems.

OxyStar Aerators are the ideal solution for upgrading, retrofitting, supplementing, or replacing underperforming aeration systems and aeration systems with excessive maintenance costs.

After installation, the overall wastewater treatment process will improve, with a noticeable increase in dissolved oxygen levels and a decrease in effluent BOD, TSS, and NH3.

Features and Benefits

- Best aeration for both efficient oxygen transfer and great mixing

- No aerosols, no misting, and fewer odors

- Low noise level

- Easy installation into any basin without dewatering the basin

- Minimal maintenance with no submerged bearings or seals

- No blowers and no blower building

- No submerged diffusers or piping to maintain

- Ideal for retrofits and upgrades to existing aeration systems

How It Works

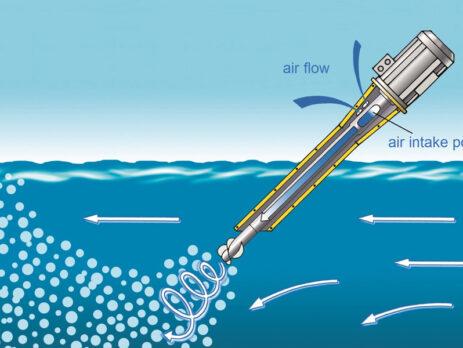

OxyStar Aspirator Aerators aerate and mix wastewater by rotating a submerged propeller. As the propeller rotates, it creates a low-pressure zone beneath the surface of the water. The pressure gradient aspirates air through the hollow shaft and discharges it into the water at a high velocity. The turbulence created by the propeller shears it into fine-bubble aeration. The OxyStar Aerator delivers mixing and aeration evenly throughout the entire basin, regardless of its size or shape. Dead spots are eliminated, and treatment is improved.

Installation

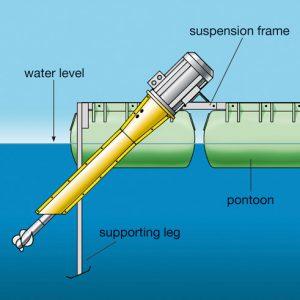

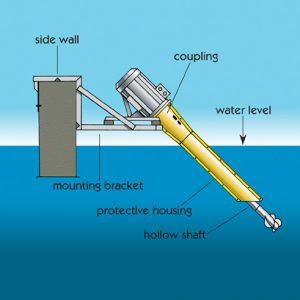

Installation is simple and versatile, using sturdy floats or adjustable mounting brackets provided with the aerator. The equipment is built to weather harsh conditions.

Reliable Industrial Wastewater Treatment

In addition to the OxyStar Aerator, Aqua-Aerobic Systems has a wide range of technologies for wastewater treatment, answering the needs of industrial customers with engineered solutions designed to achieve the desired effluent. These integrated solutions include the appropriate selection of equipment, from aerators, mixers, and bioreactors to cloth media filters, membranes, and aerobic granular sludge.

Aqua Aerobics’ wastewater treatment solutions successfully treat industrial wastewater, including:

- Food and beverage

- Pulp and paper

- Pharmaceutical

- Textiles & bleach & dye

- Chemical & Petroleum

- Landfill leachate

- Rendering

- Others

Click here to view the OxyStar Aerator brochure.

Envirep/TLC Environmental is a manufacturer’s representative for Aqua-Aerobic System in Pennsylvania, Maryland, New Jersey, Delaware, and Washington D.C.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Michael Gillespie, President at Envirep/TLC