The BEAST: Rugged and Reliable for Trucked-In Waste

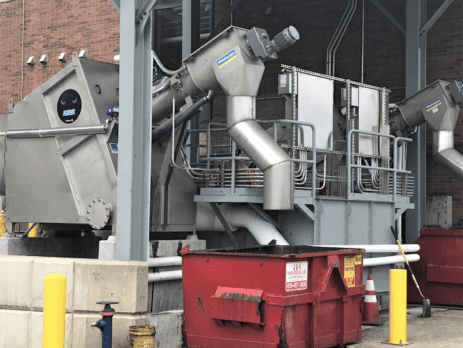

Envirep recently demonstrated The Beast at a Maryland wastewater treatment plant. The demonstration was a huge success!

The Saveco BEAST septage screen is more than just a septage receiving station—it’s a proven performer on the toughest loads. From screening debris in septage to removing inorganics from FOG (fats, oils, and grease), the BEAST handles a wide range of hauled-in wastes with ease.

Its name is well earned. Watch the video demonstration to see The BEAST in action.

Many wastewater treatment plants accept a variety of trucked-in wastes, including septic tank waste, FOG waste, municipal sludge, and industrial waste—all of which can contain solids like rags, rocks, plastics, and grease. If not properly removed, these materials can clog pumps and valves, damage downstream equipment, and reduce overall treatment efficiency.

The BEAST is a fully enclosed, self-contained, and automated receiving station designed to quickly separate solids and debris from liquids. It allows a typical septage truck to unload in just 5 to 10 minutes, all while maintaining safety and controlling odors.

How the BEAST Works: Simple, Efficient, and Built for Tough Debris

1. Direct Influent Entry

- Short influent tank design

- Waste stream flows straight into the rotating drum screen

2. Rotating Drum Screen

- Captures debris with internal flights

- Lifts and deposits solids into the auger trough

3. Auger Conveyance

- Transports debris from the trough into the washing and dewatering zones

- Integrated cleaning ensures reduced volume and odor

4. No Rock Trap Required

- Screens and augers effectively remove rocks and inorganics

- Eliminates the need for a high-maintenance grinder

5. Built to Handle the Unexpected

- Proven performance on the most challenging septage and FOG loads

- Easily processes rags, towels, T-shirts, screwdrivers, plastics, straws, rocks, and more

The dual drive feature allows the screen and auger to rotate independently and adapt to the debris load. The drum screen is at a 25° angle and rotates more slowly than the auger, which allows for better capture. The auger rotates faster to quickly remove the debris. The screen drive is located at the top of the drum and eliminates support arms at the influent end of the drum. This provides a full, unobstructed path for the flow to enter the drum. The rotating drum’s perforated plate screen, triple seal, exterior cleaning brush, and water spray nozzles provide a high capture rate, minimize by-pass, and keep even small solids, including hair, inside the screen drum.

Schedule a free on-site demo to see firsthand how you can use The Beast by SAVÉCO for septage, FOG, or sludge screening.

Contact Envirep

Envirep serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Dwight Swan