SAVÉCO Wet Well Basket Screen

The SAVÉCO Wet Well Basket Screen is used in pumping stations and treatment plants to effectively capture and remove large solids, rags, and debris from municipal and industrial wastewater.

Screening plays a vital role at wastewater treatment plants. Stones, wipes, rags, and other large debris in the wastewater ultimately end up at wastewater treatment plants clogging pumps, aeration systems, and other critical process equipment, resulting in high maintenance costs and inefficient operation.

Screening Improves WWTP Performance

Screening improves the overall performance of treatment plants by reducing the load on downstream processes and helping to improve the quality of the treated wastewater. This is an important factor in achieving discharge permits and meeting regulatory requirements.

Operating Process

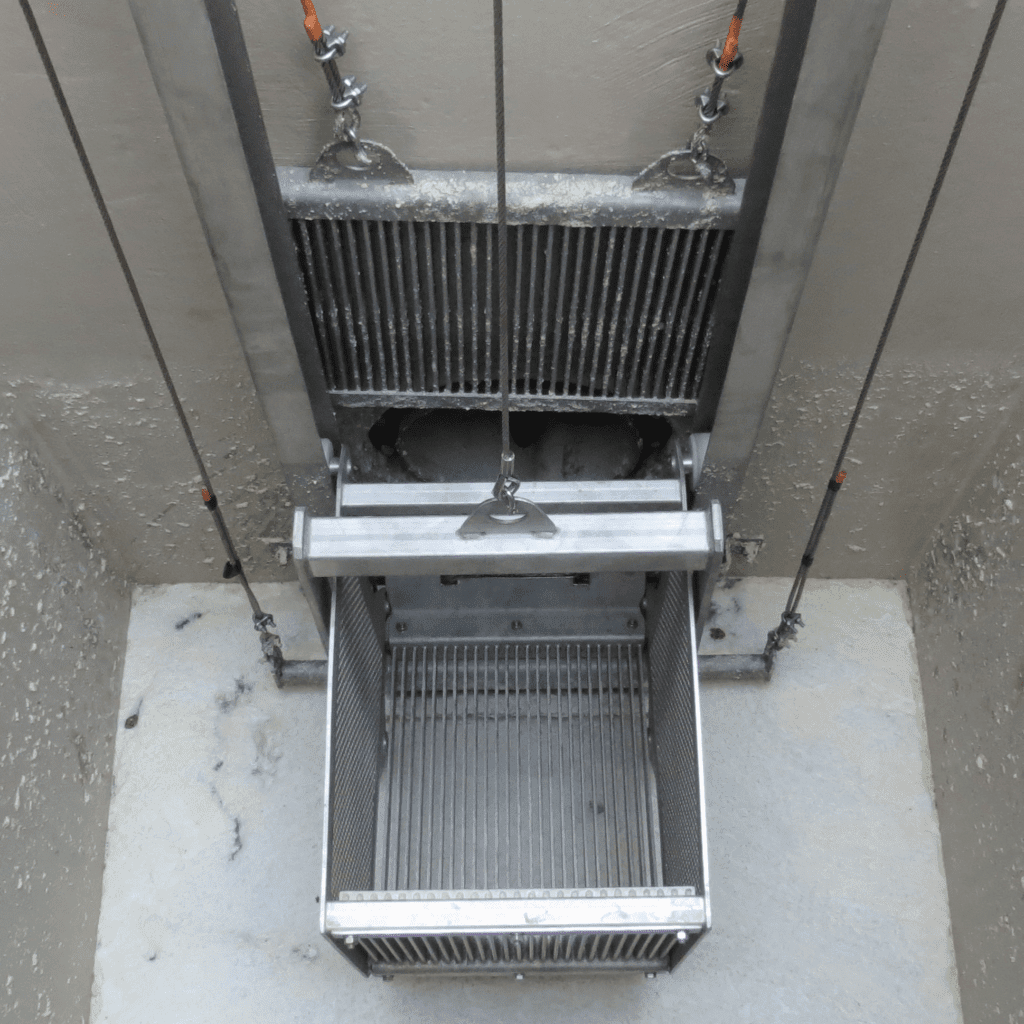

The screen basket sits below the influent pipe in the wet well to remove debris from the wastewater as the flow passes through the basket. Curved guide rails above ground allow for easy dumping of the screenings into a dumpster. The screenings drop onto a chute that directs the screenings into the dumpster.

The operator raises and lowers the screen via a local control panel with push buttons.

As the basket rises from the wet well, water drains from the screenings. The operator completes the emptying of the basket with a rake.

The basket consists of a stainless steel box with steel bars and perforated plates on the sides of the basket. When the basket is raised, a screen is lowered over the inlet to screen the wastewater entering the wet well. Therefore, no debris gets into the wet well when emptying the basket.

The equipment includes all the necessary frames and accessories required for the trouble-free and safe operation of the basket screen.

Features of the Saveco Wet Well Basket Screen

- High reliability and robust construction

- Screenings easily conveyed to the dumpster

- Stainless steel construction (304SS or 316SS)

- Cost-effective with outstanding performance

- Low maintenance costs

- Low horsepower motor for lifting basket

- Suitable for outdoor use and cold weather operation

- No spray wash required

- No manual hand crank to lift the basket

Control Panel

The SAVÉCO Wet Well Basket Screen control panel is located near the wet well in a non-hazardous location. The panel includes the power and control circuitry to properly operate the equipment and ensure compliance with applicable regulatory and safety requirements. By having the control panel located near the screen, plant operators can easily access the controls and monitor the equipment’s performance. This allows for quick and efficient adjustments to be made to the operation of the screening equipment, which can help to ensure that the process runs smoothly and efficiently.

About SAVECO

SAVÉCO of Gurnee, Illinois, supplies pretreatment screens and solids/grit equipment for water and wastewater applications.

SAVÉCO is also the exclusive sales organization for FSM in North America. This partnership allows SAVÉCO to complete its headworks product line, including the FSM perforated plate belt screen and other products.

The WAMGROUP® is a multi-national company founded as a designer and manufacturer of conveyors. The company quickly expanded into screens and solids handling equipment. They are a recognized leader in this essential industrial application with thousands of installations worldwide.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Michael Gillespie, President at Envirep/TLC