Vogelsang Rotary Lobe Reliable Sludge Pumps

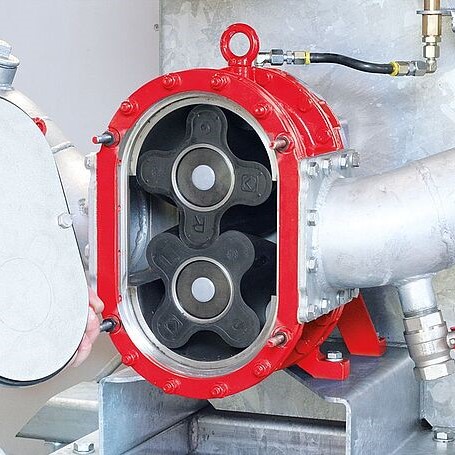

Vogelsang rotary lobe reliable sludge pumps outperform in challenging sludge applications featuring high solids content, thick and viscous sludges, and abrasive liquids. Designed with maintenance in mind, these pumps allow easy access to the entire wet end by removing the front cover, for convenient routine or preventative maintenance. Worn parts can be replaced without disturbing connected piping, ensuring minimal downtime.

Key Features

- Versatility: Effortlessly handles various liquids, including viscous, abrasive, and shear-sensitive materials.

- Performance: Ideal for municipal and industrial water and wastewater applications.

- Twisted Lobes: Vogelsang’s HiFlo® twisted lobes ensure pulsation-free pumping and longer lifetimes for the motor and coupling.

Advantages of Municipal Wastewater Sludge

- Handling Viscous Materials: Effectively manages high-viscosity fluids ensuring smooth pumping even with thick sludge.

- Abrasion Resistance: Robust construction, non-contacting design, and low operating speeds lead to longer pump life and reduced maintenance costs.

- Efficiency: Known for their high efficiency.

- Easy Maintenance: Simple and robust design for quick access and replacement of components, minimizing downtime.

- Non-Leaking: Non-leaking seals prevent leaks, ensuring the containment of hazardous or odorous sludge.

- Variable Speed Operation: Allows for precise control over the flow rate to accommodate varying sludge flow requirements.

- Small Footprint: Compact design fits in areas with limited space.

- Self-Priming: This creates a strong vacuum to start pumping sludge without manual intervention.

In summary, the advantages of rotary lobe pumps in handling municipal wastewater sludge include their ability to handle viscous and abrasive materials, gentle pumping action, self-priming capability, efficiency, ease of maintenance, and flexibility to handle varying flow requirements. These factors make them a popular choice in wastewater treatment applications.

Vogelsang Rotary Lobe Pumps have a long history of providing reliable pumping solutions at water and wastewater treatment facilities whether pumping primary sludge, secondary sludge, waste-activated sludge (WAS), thickened waste-activated sludge (TWAS), return activated sludge (RAS), septage, or slurries.

Applications at Wastewater Treatment Plants

- Sludge Transfer: Ideal for transferring thick sludge between stages of the treatment process.

- Sludge Dewatering: Used to feed sludge to dewatering processes like belt presses, centrifuges, and screw presses.

- Waste Activated Sludge (WAS) Pumping: Handles thick and dense WAS easily.

- Primary and Secondary Sludge Pumping: Ensures efficient transfer for further processing or disposal.

- Chemical Dosing: Accurately meters and transfers chemicals for treatment.

- Digested Sludge Pumping: Handles digested sludge effectively.

- Lime Slurry Pumping: Efficiently handles and meters lime slurries.

- Thickened Waste Sludge Transfer: Transfers thickened sludge for further processing or disposal.

The ability of rotary lobe pumps to handle a wide range of viscosities, solids content, and abrasive materials makes them indispensable in various critical applications within wastewater treatment plants.

Why Vogelsang Rotary Lobe Pumps?

- Robust Construction

- Innovative Design

- Ease of Maintenance

- Versatility

- Customization Options

- Excellent Customer Support

- Commitment to the Water and Wastewater Industry

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Michael Gillespie, President at Envirep/TLC