Zero-Leak H-Tec Air Release Valves – Reliable & Easy Maintenance

H-Tec zero-leakage air release valves deliver superior performance and reliability compared to traditional designs. Featuring an infinitely variable orifice, they efficiently manage both air release and vacuum break functions, simplifying valve selection and standardization across projects. The lightweight construction and minimal moving parts reduce maintenance requirements, offering a more dependable and cost-effective alternative to conventional valves.

Unlike standard air release valves that require a minimum of 3 PSI to close, the H-Tec valve seals at zero pressure. This not only eliminates leakage but also actively clears debris from the orifice, enhancing long-term performance.

Excess air in force mains can lead to pump cavitation, reduced efficiency, and accelerated wear of mechanical components. A properly functioning air release valve, such as the H-Tec, continuously vents trapped air to maintain consistent flow, protect equipment, and optimize system performance.

Easy Maintenance

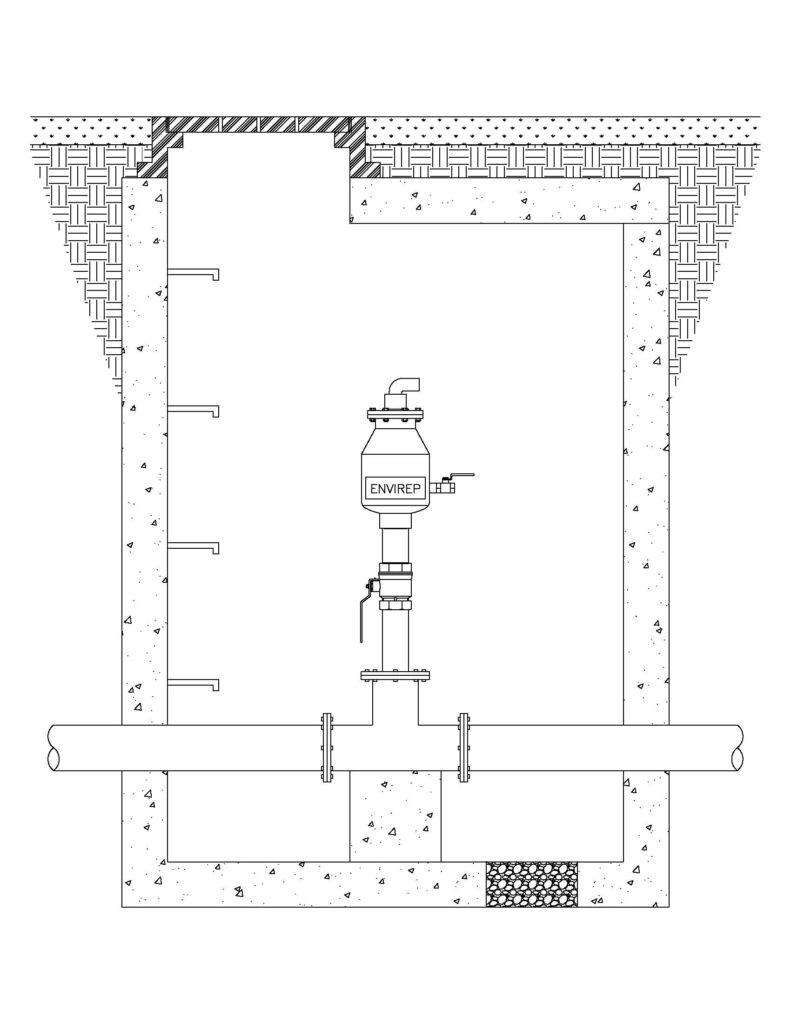

Maintaining an air release system on a force main is crucial for ensuring the pumping systems’ optimal performance and efficiency.

Many municipalities have a variety of air release valves in their collection system, with different brands, types, and models. There are no common parts and no standardization. Many of these valves are clogged, do not function correctly, and are difficult to maintain.

If you are considering replacing or upgrading your air release valves, look at the H-Tec air release valves with zero leakage. They eliminate many of the problems associated with traditional air release valves.

Key Features of H-Tec Air Release Valves

- Innovative Design – Large body, beveled bottom, smooth interior surface, and debris shield for prolonged time between cleaning.

- Non-Leaking – Drip tight sealing even at 0 psi pressure eliminating leakage common in traditional valves.

- Easy Maintenance – The working parts of the valve are easily removed through the top, and the cup seal is simple and easy to replace.

- Light Weight – At only 35 lbs, the SST valves weigh much less than a traditional air release valve making installation and maintenance much easier. The plastic valve weighs only 13.5 lbs.

- Versatile – The same H-Tec air valve functions as both an air release valve and a combination air/vacuum breaker and can be used at many similar locations.

- Simplifies Spare Parts Inventory – Using the same type of valve at every location simplifies inventory.

For more information on H-Tec valve features and benefits, click here.

Models

989 in Fiber Reinforced Plastic

990 in 316 Stainless Steel (US Made – PA Steel Compliant)

Click here to see our other manufacturers.

H-Tec offers air-release valves developed for potable & non-potable water. H-Tec valves are available in stainless steel, epoxy-coated steel, and fiber-reinforced plastic.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Joshua Price, Plant Sales at Envirep/TLC