Vogelsang XRipper Twin-Shaft Grinder

Twin-shaft grinders are known as the toughest solids reduction equipment available. They are praised for their ability to cut through tough solids and stringy waste. Everyone loves them. Well, except for the guys who service them. Unless you’re talking about the Vogelsang XRipper Twin-Shaft Grinder.

Traditional twin-shaft grinders are built with two long cutter stacks made of multiple blades and spacers — as many as 150 blade/spacer sets on the largest grinders. When it comes time for service, the blades and spacers must come apart for repair. But that’s when things go sour. Putting other twin-shaft grinder blades back together is a nightmare. Getting the spacers just right takes hours. And if you you’ve misaligned something, you have to take the whole thing apart and start over.

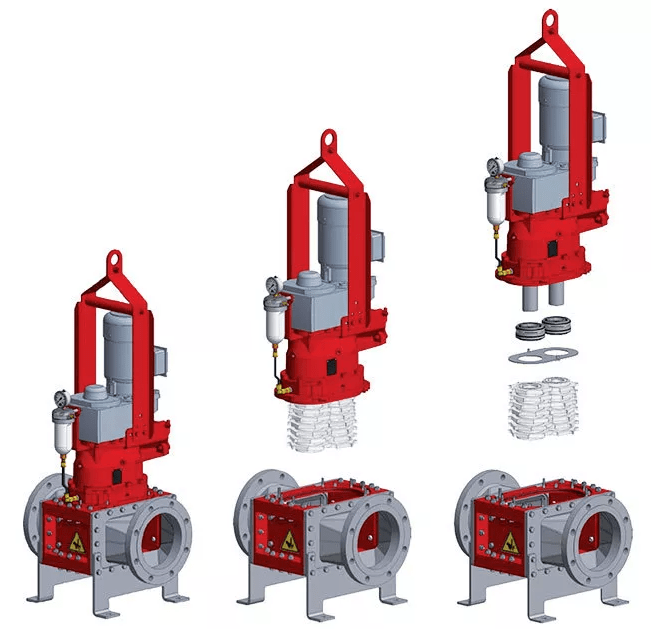

Monolithic Ripper Rotors

So Vogelsang did it differently. Instead of the nasty stack of blades and spacers, the XRipper Twin-Shaft Grinder was engineered with two monolithic Ripper Rotors, each made from one solid block of steel. No spacers, nothing to align or stack. The XRipper is also designed with no lower bearings and an easy-to-replace cartridge mechanical seal.

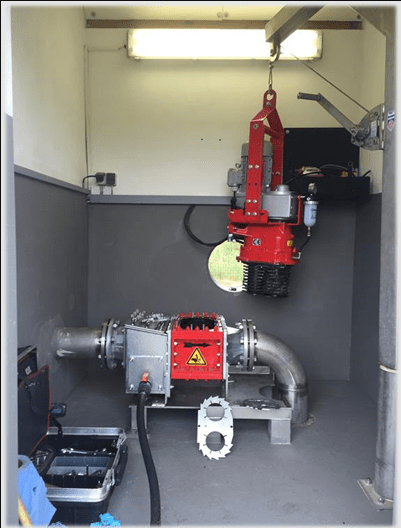

Unlike a traditional twin-shaft grinder, the XRipper grinder is easy to maintain. Everything can be done inline without removing any connected piping. Simply remove a few retaining hex nuts, and the unit can be lifted vertically while the flanges and housing remain connected to the piping.

The XRipper’s ripper blades are removed at the same time and come off in solid sections versus individual pieces like ordinary twin-shaft grinders. Typical routine service such as changing ripper blades takes only a fraction of the time. In addition, there are no cartridge-style parts that require factory refurbishment.

Vogelsang makes it easy to replace a traditional twin-shaft grinder with a drop-in replacement for many common grinders in the market.

Advantages of the Vogelsang XRipper Grinder

- Reduces clogging: Wastewater twin shaft grinders shred large solids into smaller pieces, reducing the likelihood of clogs in downstream equipment.

- Improves efficiency: By reducing the size of the solids in the wastewater, the twin shaft grinder improves the efficiency of downstream processes.

- Protects equipment: By removing large solids from the wastewater, the twin shaft grinders protect downstream equipment from damage and wear.

- Improves quality of effluent: The twin shaft grinder helps improve the quality of the effluent discharged from the treatment plant.

- Lowers maintenance costs: The twin shaft grinder reduces maintenance costs associated with downstream equipment.

- Reduces odors: The twin shaft grinder helps reduce odors associated with wastewater treatment by processing solids more efficiently and preventing accumulation.

In conclusion, Vogelsang XRipper twin-shaft grinders improve the performance and efficiency of a wastewater treatment plant, reduce maintenance costs, and improve the quality of the effluent.

Contact Envirep

Envirep/TLC serves the municipal and industrial water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, the District of Columbia, Virginia, and West Virginia.

Do you need help selecting the right equipment for your application? Contact Envirep at 717-761-7884 or sales@envirep.com.

By Joshua Price, Plant Sales at Envirep/TLC