Gorman-Rupp’s Pump Control Panels with VFDs

During the past two decades, the wastewater industry has significantly increased the use of variable frequency drives (VFDs). Gorman-Rupp’s VFD control panels offer superior wastewater flow control compared to constant-speed pumps in wastewater pumping stations. This is beneficial as utilities seek ways to reduce power costs.

Advantages of Gorman-Rupp’s VFD Control Panels:

- Power Savings: VFDs help reduce energy consumption.

- Enhanced WWTP Processes: They improve wastewater treatment plant processes.

- Reduced Risk of Overloading Downstream Sewer: VFDs ensure that the pumping rate matches the inflow.

- Extended Equipment Life: Soft start and stop features extend the life of pumps, motors, valves, and couplings.

- Reduced Current and Voltage Fluctuations: VFDs reduce inrush current and voltage dips, minimizing stress on the system.

- Reduced Water Hammer: They reduce the potential for water hammer, protecting the system from damage.

- Flexibility: VFDs provide the flexibility to change the pumping rate as needed.

Gorman-Rupp’s Pump Control Panels with VFDs:

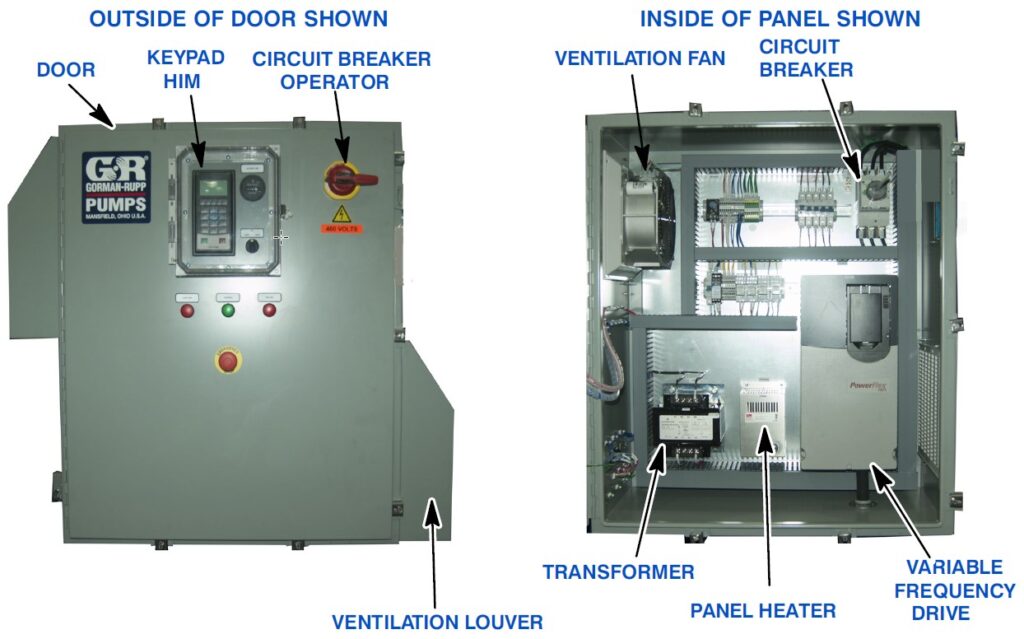

- Standard Product: These panels come in NEMA 3R steel enclosures with panel heaters and ventilation fans.

- Key Features: They include a lockable main circuit breaker, Hand-Off-Auto selector switch, elapsed time meter, and a door-mounted keypad message center (HIM-Human Interface Module).

- Safety Features: The panels have a door-mounted disable push button and indicating lights for pump run, VFD fault, and no flow/load.

- Drive Details: They use Allen-Bradley Power Flex 753 variable frequency drives and are UL-listed.

- Remote Operation: The panels allow for remote start/stop operation with panel connectors for inputs.

- Sensor Options: They can be set up for two float inputs (start and stop levels at a preset speed) or a single transducer input (level and pressure).

- Monitoring: Dry contacts are provided for monitoring drive run, drive faulted, no flow/load, and torque/power out-of-range alarms.

- Shipping: Control panels are available to ship from Gorman-Rupp in four weeks or less.

Lift Station VFD Control Panels from Gorman-Rupp:

- Customized Control: These panels are designed to precisely match controls to pumps and motors, ensuring optimal system performance.

- Liquid Level Control Options: Customers choose from four liquid level control options when selecting a Gorman-Rupp ReliaSource solids-handling pump package.

- Reliable Performance: Gorman-Rupp control panels offer simple, reliable performance, with features for accurate start/stop operation, alternation, level sensors, pump delay, and alarms.

- Advanced Control Systems: Some panels include soft starters or variable frequency drives (VFDs) to manage electric inrush, hydraulic shock, and starting and stopping torque-based management and monitoring.

Contact Envirep

Envirep/TLC serves the water and wastewater market in Pennsylvania, New Jersey, Maryland, Delaware, DC, Virginia, and West Virginia.

Contact Envirep at 717-761-7884 or sales@envirep.com.

By Joshua Price, Plant Sales at Envirep/TLC